Table of Contents

ToggleHow to Ensure Your Puzzles Bulk Safe Shipping?

For Puzzle and Games Manufacturer/exporter,to bring these products safe to customer’s warehouse is very essential.

Hence, it requires manufacturers to do all the measures to protect the bulk safe and in good status.

This article will delve into the safety measures through before shipping .

Table of Contents

Transportation Testing Methods

These tests replicate the movements, forces, impacts, shocks, vibrations, temperatures, and pressures the products will most likely meet during transportation.

Main test as below:

DROP TEST

This test creates the effect of a drop,dropping a parcel onto the ground to evaluate the damage or deformation.

It provides insight into the Product’s vulnerability or tolerance while determining the effect of the cushioning or protection features of the package.

The regular height is commonly used heights in drop testing are around 90cm (approximately 3 feet) to 100cm (approximately 3.3 feet)from the ground.

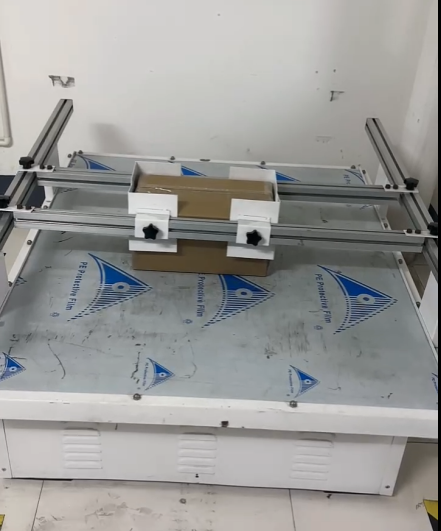

A drop tester machine can be used for this test. This machine can also control the height, angle, acceleration, and rate of frequency of the drops.

VIBRATION TEST

This test is based on simulated vibration levels that occur during the transport of a package. It is designed to replicate the road, rail, air, or sea vibrational level and assess the damage that would cause during transportation.

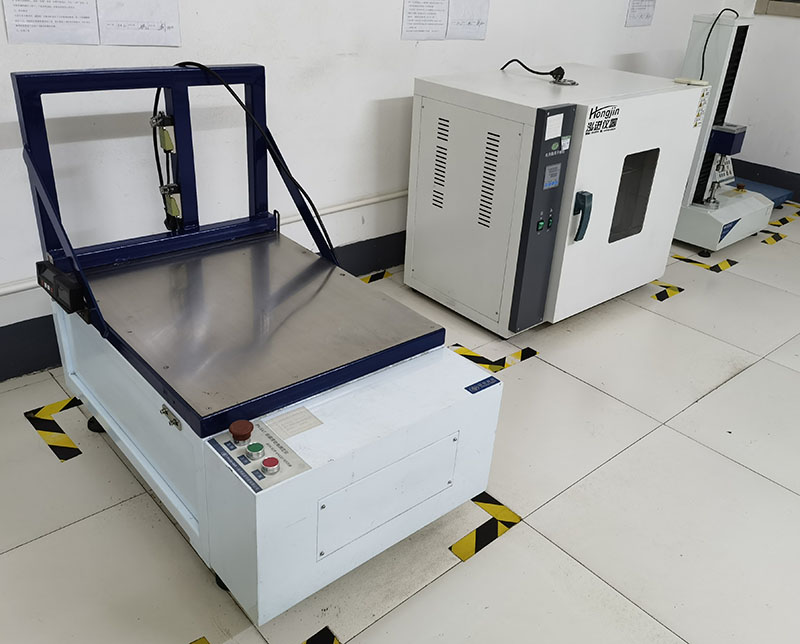

The vibration test can be carried out using a vibration tester machine that can control the magnitudes, frequencies, durations, and directions of the vibrations.

Notably, this testing system can determine if the wear and tear of the product occurs due to loosening in the product or between the package and the product.

By now,Most factory use this machine to do test. It usually last at least 3 hours,one hour for each side(Up,Down and Side)

COMPRESSION TEST

The pressure test of a package simulates the compression of the package or product by stacking products on each other. Using a compression tester machine, where the pressure, speed, and duration are controlled, manufacturers measure the strength and structural integrity of the packaging, pointing out buckling and crushing of the product. It will also indicate the distribution or load transfer in the package.Usually the Packaging Materials such as Boxes, containers, and pallets needs compression test.

Besides this,Electronics and Appliances,Furniture,Automotive Parts,Food and Beverage Containers,Medical Supplies and Equipment,Building Materials also need to do compression test.

CLIMATIC TEST

Another essential test carried out is a climate test that reproduces certain weather conditions likely to be experienced by the by-products contained inside a package. Relevant parameters are added in this test, including temperature, humidity, or pressure, to reveal the effects on the appearance of the product and its package.

This test can show the degradation or erosion of the material. Also, the test is usually conducted in a climatic chamber machine that has an environment with controlled factors such as temperature, humidity, pressure, and light.climatic testing is essential for products sensitive to environmental conditions, including electronics, pharmaceuticals, food and beverages, cosmetics, chemicals, automotive parts, and agricultural products. This testing simulates various climates to ensure product stability, efficacy, and quality during shipping and storage, considering factors like temperature, humidity, and atmospheric pressure changes.

Choosing The Right Shipping Partners

For Puzzle manufacturer,the main part of shipping is local truck and Sea shipment.

You need to choose the reliable and good reputation shipping company to arrange goods by truck. Here is the brand in the market

- Maersk

- Carnival Cruise Line

- CMA CGM

- MSC Mediterranean Shipping Company

Tracking And Handling During Transit

Based on forwarder’s bill of loading,you can check the shipping status from website and See the whereabouts and condition of our cargo. This minimizes delays and possible harm by enabling proactive issue detection and mitigation.

Tips For Buyers And Importers To Ensure Safe Product Delivery

Select Reputable Suppliers: Partner with suppliers who have a strong track record of quality and reliability.

Define Quality Standards: Clearly communicate your quality and testing requirements.

Inspect Products Pre-Shipment: Conduct or hire third-party inspections before shipping.

Monitor Shipping Conditions: Use tracking and monitoring tools to oversee shipping conditions.

Understand Regulations: Be well-versed with import/export regulations and compliance standards.

Establish Clear Contracts: Include quality, delivery terms, and penalties for non-compliance in contracts.

Plan for Logistics: Choose reliable logistics partners and ensure appropriate packaging for transportation.

Conclusion

Shipping and delivering bulk is a delicate process that must be watched closely to protect the integrity of the products. Everyone, from the manufacturers and the shipment company to the maritime officers, has a role to play before the final preserved products are delivered to customers.

We’ve all highlighted the complicated and delicate process your jigsaw puzzles and games go through before they reach your hand.Hope this article can help you to learn more about it.

Bella

Contact Us for Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “@jabaygames.com”.